#chapati making machine manufacturer

Explore tagged Tumblr posts

Text

Case Studies: Successful Implementation of Chapati-Making Machines

The food industry continuously seeks innovations to streamline processes and improve efficiency. One such innovation is the chapati-making machine, which has revolutionized the preparation of this staple food in many commercial kitchens. Here, we explore a few case studies highlighting the successful implementation of chapati-making machines by leading chapati making machine manufacturers.

Case Study 1: Catering Services in Delhi

To satisfy the enormous demands of weddings and events, a well-known catering firm in Delhi looked to improve its chapati production. They added a completely automatic chapati-making machine to their operations by collaborating with chapati-making machine manufacturers. The outcome of this implementation was:

A 50% boost in output capability.

Chapatis of uniform size and quality.

Substantial decrease in the cost of manual labor.

The caterer stated that they were able to serve big groups of people with ease and maintain a high level of customer satisfaction because of the machine's dependability and effectiveness, which were supplied by the chapati-making machine manufacturers.

Case Study 2: Restaurant Chain in Mumbai

During peak hours, a well-known restaurant chain in Mumbai struggled to maintain the uniformity and speed of chapati preparation. They placed semi-automatic chapati-making machines throughout their locations after speaking with a reliable chapati-making machine manufacturer. The outcomes were striking:

40% less time was spent on preparation.

Chapatis that are all the same thickness and size.

Increased productivity in the kitchen.

The restaurant business admitted that the chapati-making machine's manufacturer knowledge and assistance were essential to attaining these advancements.

Case Study 3: Industrial Canteen in Bangalore

To meet the tremendous demand for chapatis, an industrial cafeteria in Bangalore that serves thousands of meals every day sought a solution. They adopted a high-capacity chapati-making machine in partnership with a forward-thinking chapati-making machine manufacturer. As a result of the implementation:

More than 2,000 chapatis are produced per hour.

Despite large volumes, quality remains constant.

Enhanced cleanliness and hygienic conditions throughout production.

The chapati-making machine manufacturers were commended by the canteen management for their innovative technology and smooth integration, which significantly increased their operating efficiency.

These case studies demonstrate the transformative impact of chapati-making machines in various commercial and institutional settings. The expertise and advanced technology provided by chapati-making machine manufacturers have enabled businesses to increase efficiency, maintain consistent quality, and reduce labor costs. Whether in catering services, restaurants, industrial canteens, school meal programs, or luxury hotels, the role of a reliable chapati-making machine manufacturer is crucial in achieving these successes. The continued innovation and support from these manufacturers ensure that chapati-making machines remain an integral part of modern food preparation.

The landscape of kitchen technology is ever-evolving, and chapati-making machines are no exception. With the growing demand for automation and efficiency in food preparation, chapati-making machine manufacturers are continuously innovating to meet these needs.

The combination of advanced automation and artificial intelligence (AI) is one of the most important trends. Chapati-making machine manufacturers are creating devices that can instantly modify settings in response to climatic conditions and the consistency of the dough. With little assistance from humans, AI-powered devices can ensure flawless chapatis by learning from previous experiences to increase productivity and consistency.

Chapati-making machine manufacturers will provide more personalization in their future designs. To meet particular needs, consumers will be able to modify characteristics like size, thickness, and cooking time using machines. Because of their adaptability, chapati machines can be used in a wide range of settings, from small homes to expansive commercial kitchens.

The rise of the smart kitchen means that chapati-making machine manufacturers are developing models that can connect with other smart appliances. These machines will be able to sync with kitchen management systems, providing real-time data and enhancing overall kitchen efficiency.

Sustainability is a growing concern in all industries, and chapati-making machine manufacturers are no exception. Future designs will incorporate eco-friendly materials and manufacturing processes, reducing the environmental impact of these machines.

As commercial kitchen space becomes more valuable, chapati-making machines, fully automatic designs will become more compact and space-efficient. These new models will be designed to fit seamlessly into various kitchen layouts without compromising on their output capacity or functionality.

When designing kitchen equipment, safety is still of utmost importance. Chapati-making machines fully automatic would have sophisticated safety features like temperature control, automatic shut-off, and integrated sensors to identify problems. In crowded kitchen settings, these characteristics will guarantee safe operation and lower the possibility of mishaps.

With so many improvements in the works, the future of completely chapati-making machines fully automatic is bright. Among the themes influencing this developing technology are increased automation, the integration of artificial intelligence, greater customization, enhanced energy efficiency, user-friendly interfaces, small designs, sophisticated safety measures, integration of smart kitchens, expanded manufacturing capabilities, and sustainability. Chapati-making machines fully automatic will be essential in revolutionizing the production of chapatis as they develop further, improving its consistency, efficiency, and usability in both home and commercial kitchens.

#Chapati making machine manufacturer#Chapati making machine#chapati maker#Chapati making machine fully automatic

0 notes

Text

Flour Machine: Chapati Making Machines – Health and Safety Considerations

When it comes to setting up a food business focused on Indian cuisine, particularly one that involves making chapatis, investing in the right equipment is crucial. Chapati making machines, also known as flour machines or roti makers, are indispensable tools for efficiently producing high-quality chapatis. However, as with any food processing equipment, it's essential to prioritize health and safety considerations to ensure a safe working environment and maintain product quality.

#Chapati making machine manufacturers#chapatti making machine suppliers#Chapati making machines#chapati making#chapati machine manufacturers#chapati machine suppliers#chapati

0 notes

Text

0 notes

Text

#Papad Making Machine Manufacturer in Ahmedabad#pani puri making machine in Ahmedabad#chapati Making Machine Manufacturer in Ahmedabad

0 notes

Text

Stainless Steel: A Key Ingredient for Success in India’s Chapati Machine Market

The role of stainless steel in the manufacturing of commercial chapati machines is integral, and it’s a story that involves key sectors like stainless steel suppliers, welding, and MSMEs. Stainless steel’s versatility, durability, and resistance to corrosion make it the material of choice for constructing components that can withstand the high demands of food production while maintaining hygiene and safety standards.

Stainless Steel Suppliers and Their Role in Chapati Machine Manufacturing

Stainless steel suppliers are essential for ensuring a steady flow of high-quality materials needed to produce chapati machines. These suppliers provide stainless steel sheets, pipes, and components, which are vital for building the machine’s frame, cooking plates, and other essential parts. The quality of the stainless steel directly affects the performance and longevity of the machine, making these suppliers crucial players in the supply chain. As the demand for chapati machines grows in both domestic and international markets, stainless steel suppliers are stepping up to meet the increasing needs of the food machinery industry.

The process of stainless steel welding is pivotal in ensuring that the components of a chapati machine are securely joined together. Stainless steel welding enables manufacturers to assemble parts like the rollers, heating plates, and the structural frame, which need to be both strong and resistant to wear. This welding technique ensures that the machine can operate smoothly for long periods under heavy use. Furthermore, stainless steel's resistance to corrosion guarantees that the machines can maintain their durability, even in high-moisture environments, which is crucial for food production.

Stainless Steel Pipes in Chapati Machine Operations

Stainless steel pipes are also vital components in chapati machines, supporting functions like dough transportation, heat regulation, and mechanical movement. These pipes help in transferring the dough from one stage to another while ensuring consistent heat distribution across the cooking plates, essential for perfect chapatis. The strength and resilience of stainless steel pipes ensure that the chapati machines run efficiently, even in high-volume production settings.

The Impact of MSMEs and the Indian Economy

MSMEs in India are leading the charge in producing high-quality chapati machines, supported by advanced stainless steel components. These small and medium enterprises are driving innovation, not only by manufacturing top-tier food machinery but also by creating employment opportunities and boosting India’s economy. The growth of MSMEs in the food machinery sector is a testament to the country's focus on developing locally manufactured products that cater to both domestic needs and export markets.

As India continues to expand its manufacturing base, the collaboration between stainless steel suppliers, welding specialists, and MSMEs will remain vital to the success of the chapati machine industry, ultimately contributing to the nation's economic growth.

#high-quality chapati machines#food machinery#stainless steel suppliers#sunshine industries#chapati machine

0 notes

Text

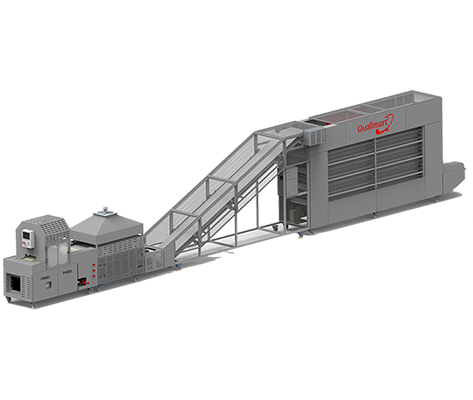

Paratha making machine fully automatic - Grisham Industry

Paratha is one of the most popular and traditional foods of the Indian Subcontinent. They are also known as soft, unleavened flatbread made from whole wheat in thick layers, unlike chapati which is thinner. Parathas are typically cooked on a griddle with ghee or oil, resulting in a golden, crispy exterior and a soft, flavourful interior.

Introducing the Automatic Paratha Making Machine – a revolutionary innovation designed to transform the traditional art of paratha preparation in industrial kitchens. This cutting-edge machine organizes and automates the entire Paratha-making process, from kneading the unleavened dough to the final flatbread. Parathas, being a staple food in Indian households, are characterized by their thin, flaky layers and rich, flavourful fillings.

As a result, this innovation not only benefits businesses in terms of efficiency and cost-effectiveness but also contributes to the preservation and popularization of traditional culinary delights on a larger scale. The fully automatic paratha-making machine stands as a testament to the fusion of technology and gastronomy, making the joy of relishing authentic parathas accessible to all.

For more details please visit our website: https://grishamindustry.com/semi-automatic-half-cooked-paratha-making-machine-manufacturer-coimbatore-kerala-tamilnadu-india/

0 notes

Text

Automatic Chapati Machine Manufacturer — Deepam Kitchen Machineries

Automatic Chapati Machine Manufacturer — Deepam Kitchen Machineries, offers a cutting-edge solution with its high productivity, quality, and consistency making it the go-to choice for many food businesses. Deepam Kitchen Machineries places a strong emphasis on hygiene.

The machine is built for ease of use, featuring intuitive controls and an easy-to-navigate interface. Even staff with limited technical skills can quickly master its operation, adjusting settings for size, thickness, and cooking temperature, ensuring a hassle-free experience in any busy kitchen.

Click here to know more about Automatic Chapati Machine Manufacturer.

Deepam Kitchen Machineries

Contact: 9566659950, 9585800900, 9363619950

Website: https://deepamkitchen.com

#commercialkitchenequipments#commercialkitchenequipment#kitchenequipmentmanufracturer#steamcookingequipment#steamboilers#kitchenequipmentmanufacturers#steamcookingsystemmanufacturer#idlysteamer

0 notes

Text

Best Commercial Atta Chakki(Flour Mill) Manufacturer in India | Sonar Appliances

In a nation where staple foods such as chapatis, parathas, and a variety of traditional dishes rely heavily on fresh flour, the importance of quality flour mills, or atta chakkis, cannot be overstated. India, with its diverse culinary heritage, demands reliable and efficient flour milling solutions. Among the prominent names in this domain, Sonar Appliances stands out as a leading manufacturer of Commercial Atta Chakki, revolutionizing the way flour is produced in many establishments.

The Need for Commercial Atta Chakkis

In the bustling food industry, whether it’s restaurants, bakeries, or catering services, consistency and quality in flour play a crucial role in delivering the perfect dishes. Commercial Atta chakki are designed for high-volume flour milling, helping businesses maintain quality while meeting the growing demand for flour products. Traditional mills may not suffice for larger operations, making efficient and durable commercial mills essential.

Why Choose Sonar Appliances?

Quality and Durability

Sonar Appliances is synonymous with quality. Each Atta Chakki is crafted from high-grade materials that ensure durability and longevity. These machines are designed to withstand continuous use, making them ideal for commercial settings. The robust construction guarantees minimal maintenance, reducing downtime for businesses.

Advanced Technology

The innovative engineering behind Sonar’s Flour Mills incorporates the latest technological advancements, ensuring consistent grind quality and effective milling. With features such as adjustable grinding settings, users can customize the fineness of the flour to meet specific culinary needs. This flexibility is critical for businesses that serve diverse clientele with varying preferences.

Energy Efficiency

In today’s eco-conscious environment, energy efficiency is a significant concern for businesses. Sonar Appliances takes pride in developing flour mills that not only deliver high performance but also optimize energy consumption. This approach not only reduces operational costs but also minimizes the environmental footprint of flour milling operations.

User-Friendly Design

Sonar’s Commercial Atta Chakki are designed with the end-user in mind. Simple operation interfaces and easy-to-follow instructions ensure that staff can quickly learn to use the machines effectively. This user-friendly aspect is vital in busy kitchens where time is of the essence.

Exceptional Customer Support

Sonar Appliances doesn’t just stop at selling machines; they offer comprehensive customer support. From installation to regular maintenance and troubleshooting, their dedicated support team ensures that businesses face minimal interruptions in their operations. This commitment to customer service builds lasting relationships and trust.

Applications of Sonar Commercial Atta Chakkis

Sonar’s atta chakkis have found applications in various sectors, including:

Restaurants and Cafes: Ensuring a steady supply of fresh flour for daily operations.

Baking Units: Providing the right flour consistency for bread, pastries, and other baked goods.

Catering Services: Facilitating mass production of flour-based dishes for events and gatherings.

Flour Distribution: Enabling small-scale flour manufacturers to process and supply high-quality flour to local markets.

Conclusion

As the demand for high-quality flour continues to rise, investing in a Commercial Atta Chakki is an intelligent decision for businesses in the food industry. Sonar Appliances has emerged as the best Commercial Atta Chakki Manufacturer in India, combining quality, technology, and customer-centric service to meet the evolving needs of the market. With a dedication to excellence and a passion for innovation, Sonar Appliances is not just a manufacturer but a trusted partner for those seeking to elevate the standard of their flour products. If you��re looking to enhance your business operations and ensure the highest quality in your flour output, consider Sonar Appliances as your go-to solution.

Contact Us

India

Sonar Appliances

Visit: https://sonarappliances.com/products/Commercial/Sonar-Flour-Mill

Call Us: +91 9312248787

Mail At: [email protected]

ADD- E-77, West Vinod Nagar, Near Mayur Public School, Behind Mother Dairy, Patparganj, Delhi, 110092, India

#CommercialAttaChakkiMachine#AttaChakkiMachine#AttaChakkiMachines#AttaChakkiBestCommercialFlourMill#AttaChakkiCommercialMachine

0 notes

Text

Best Commercial Atta Chakki Machine in India for fresh and pure atta | Sonar Appliances

In a country like India where roti, chapati, and other wheat-based delicacies hold a special place in the hearts and plates of millions, having access to fresh and pure atta (wheat flour) is crucial. This is where Commercial Atta Chakki Machine come into play, revolutionizing the way atta is processed and ensuring that the final product is of the highest quality. Among the many brands vying for the top spot in this market, Sonar Appliances stands out as a trusted name delivering exceptional performance and quality products.

When it comes to choosing the Best Commercial Atta Chakki Machine in India, several factors come into play, including efficiency, durability, ease of use, and most importantly, the end product – fresh and pure atta that retains all the nutrients and flavor of the wheat. Sonar Appliances excels on all these fronts, making it a popular choice among commercial establishments and individuals looking to set up a small-scale atta processing unit.

One of the key features that set Sonar Appliances apart is its commitment to quality and innovation. The brand uses advanced technologies and high-quality materials to manufacture Atta Chakki Machines that are not only efficient and durable but also easy to maintain. This ensures that users can focus on their business without worrying about frequent breakdowns or maintenance issues.

Furthermore, Sonar Appliances offers a range of Commercial Atta Chakki Machines to suit different needs and budgets. Whether you are looking for a compact machine for a small bakery or a high-capacity unit for a large-scale production facility, Sonar Appliances has you covered. These machines are designed to process wheat grains efficiently, resulting in finely ground atta that is free from contaminants and retains the natural taste and aroma of the wheat.

Another aspect that makes Sonar Appliances a top choice for commercial atta chakki machines is its after-sales service and customer support. The brand has a dedicated team of professionals who are always ready to assist customers with any queries or issues they may have. This commitment to customer satisfaction has earned Sonar Appliances a loyal customer base and rave reviews in the industry.

In conclusion, when it comes to choosing the Best Commercial Atta Chakki Machine in India for fresh and pure atta, Sonar Appliances emerges as a clear winner. With its focus on quality, innovation, and customer satisfaction, the brand has earned a reputation for delivering top-notch products that meet the needs of businesses and individuals alike. So, if you are in the market for a reliable and efficient atta chakki machine, look no further than Sonar Appliances – your partner in producing the finest quality atta for your culinary endeavors.

Contact Us

India

Sonar Appliances

Visit: https://sonarappliances.com/products/Commercial/Sonar-Flour-Mill

Call Us: +91 9312248787

Mail At: [email protected]

ADD- E-77, West Vinod Nagar, Near Mayur Public School,

Behind Mother Dairy, Patparganj, Delhi, 110092, India

#Commercial Atta Chakki Machine#Atta Chakki Machine#Atta Chakki Machines#Best Commercial Flour Mill#Atta Chakki Commercial Machine#Commercial Atta Chakki Machine in Delhi#Best Commercial Atta Chakki For Business#Top Commercial Atta Chakki#Commercial Atta Chakki at Best Price

0 notes

Text

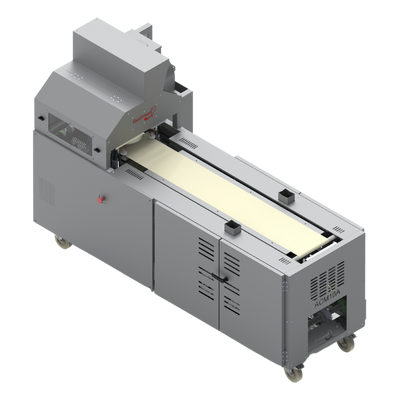

Revolutionizing Your Kitchen: The Semi-Automatic Chapati Making Machine

In a world where time is increasingly valuable, kitchen automation has become a significant trend. Among the many innovations designed to save time and effort in food preparation, the Semi-Automatic Chapati-Making Machine stands out. This appliance is transforming how chapatis, a staple in many households, are prepared, offering convenience without sacrificing the authentic taste and texture of homemade chapatis.

What is a Semi-Automatic Chapati Making Machine? A semi-automatic chapati-making machine is a kitchen appliance that streamlines the process of making chapatis or rotis. Unlike a fully automatic machine, which handles the entire process from dough kneading to cooking, a semi-automatic machine requires some manual intervention. Typically, users prepare the dough and place it into the machine, which then rolls out, flattens, and partially cooks the chapati. The final cooking, which involves achieving the perfect puff and golden-brown spots, is done manually on a griddle or tawa.

Benefits of Using a Semi-Automatic Chapati Making Machine 1. Time Efficiency One of the most significant advantages of using a semi-automatic chapati maker is the time it saves. Rolling out chapatis by hand can be a time-consuming process, especially when making them in large quantities. The machine quickly flattens the dough into evenly sized chapatis, reducing the time spent in the kitchen.

2. Consistent Results Achieving the perfect round and uniformly thin chapatis can be challenging, especially for beginners. A semi-automatic chapati maker ensures consistent results every time. The machine rolls out dough balls into uniform shapes and thickness, ensuring that each chapati cooks evenly and looks perfect.

3. User-Friendly These machines are designed to be easy to use, even for those who are not particularly skilled in cooking. The controls are simple, and the process is straightforward: prepare the dough, load it into the machine, and let it do the rolling. This user-friendliness makes it an excellent tool for busy households, where time and convenience are essential.

4. Energy Efficiency Semi-automatic chapati makers consume less energy compared to their fully automatic counterparts. Since they require manual intervention for the final cooking stage, they do not use as much electricity. This makes them an eco-friendly option for those looking to reduce their energy consumption.

5. Cost-Effective Compared to fully automatic machines, semi-automatic chapati makers are generally more affordable. They provide a good balance between automation and manual control, offering value for money without compromising on quality.

How to Use a Semi-Automatic Chapati Making Machine Using a semi-automatic chapati maker is simple:

Prepare the Dough: Knead the dough as you normally would. Make sure it's of the right consistency – neither too soft nor too hard.

Preheat the Machine: Most machines require a few minutes to heat up. Check the manufacturer's instructions for the exact time.

Place Dough Balls: Divide the dough into small, even-sized balls and place them in the designated area of the machine.

Roll and Press: The machine will automatically roll and press the dough balls into flat chapatis.

Cook on a Griddle: Once the chapatis are rolled out, transfer them to a hot griddle or tawa for the final cooking stage. Flip them until they puff up and develop golden-brown spots.

Conclusion The Semi-Automatic Chapati-Making Machine is a game-changer for anyone who regularly makes chapatis. It combines the best of both worlds: the convenience of automation with the control and authenticity of manual cooking. Whether you're a busy professional, a homemaker, or someone who loves cooking but could use some help in the kitchen, this machine can make your life easier, saving you time and effort while ensuring that you still enjoy delicious, homemade chapatis.

0 notes

Text

Chapati Making Machine Manufacturer - Trident Engineers.

The Chapati Making Machine by Trident Engineers is a high-efficiency appliance designed for commercial kitchens, hotels, and restaurants. Its robust construction ensures durability, while intuitive controls make operation easy. This machine is engineered for maximum efficiency, capable of producing a large number of chapatis within a short span of time.

With versatility to produce chapatis of various sizes and thicknesses, along with other flatbread, it’s a hygienic, energy-efficient solution with a compact footprint, ensuring reliable performance for bulk chapati production. Built with sturdy materials and precision engineering, the Chapati Making Machine is durable and long-lasting. Click here to know more about Chapati Making Machine.

Trident Engineers.

Contact: 95009 88122, 95001 55206

Website: https://rishabtte.com/

#commercialwetgrinder#commercialwetgrinderincoimbatore#wetgrinders#tiltingwetgrindermanufacturers#tiltingwetgrinder#wetgrinder#wetgrinderindia#commercialwetgrinders

0 notes

Text

How Automatic Roti Maker Machines Can Simplify Your Cooking?

Although cooking is a necessary daily task, it can frequently be labor-intensive and time-consuming. An automatic roti maker machine can be a lifesaver for people who love homemade, fresh rotis but find the preparation process tiresome. These cutting-edge gadgets are made to make preparing rotis easier and save you time and effort. This post will discuss the benefits of investing in an automatic roti maker machine and how it may improve your cooking experience.

1. Time-Saving Practicality

The time that an automatic roti maker machine saves is among its biggest benefits. The dough is kneaded, rolled out, and cooked separately for each roti in the traditional method. The entire procedure is expedited with an automatic roti maker machine. All you have to do is prepare the dough and feed it into the machine; it will do the rest. As the machine takes care of the labor, you may concentrate on other cooking duties or even unwind.

2. Reliable Quality

Every roti is cooked to perfection thanks to an automatic roti maker machine. Rotis are consistently cooked thanks to the constant heat and pressure maintained by these devices. With hand preparation, where variables like rolling technique and temperature control can change, this uniformity can be difficult to attain. You may have hassle-free, perfectly round, and evenly cooked rotis with an automatic roti maker machine.

3. Usability

It is really easy to use an automatic roti maker machine. Even inexperienced cooks can use the majority of models because they include easy-to-use controls and clear instructions. The automatic procedure lowers the learning curve, allowing you to begin creating mouthwatering rotis immediately. Whether you're a novice cook, a busy professional, or a home cook with little time, an automatic roti maker machine may make the procedure simple and fun.

4. Advantages for Health

You can ensure a healthier supper by controlling the ingredients used in your rotis with an autonomous roti maker machine. To make personalized rotis, you can use whole wheat flour, add herbs and spices, or add other wholesome components. Store-bought rotis frequently lack this level of control since they may contain hazardous ingredients or preservatives. Your family will have a healthier, more nourishing supper if you prepare your own rotis at home using an automatic roti maker machine.

5. Adaptability

Numerous automatic roti maker machines are multipurpose and may be used to manufacture a variety of flatbreads, including tortillas, parathas, and chapatis. Because of its adaptability, you may try out various recipes and cuisines without requiring a variety of appliances. Purchasing an automatic roti maker machine expands your culinary skills and gives your kitchen a multipurpose tool.

6. Efficiency of Energy

Compared to conventional stovetop cooking, modern automatic roti maker machines use less energy because of their energy-efficient design. This makes them an eco-friendly option in addition to lowering your energy costs. Choosing an automatic roti maker machine that uses less energy helps to promote more sustainable cooking methods.

7. Simple Upkeep

An automatic roti maker machine is easy to maintain. The majority of models have easily cleaned detachable pieces and non-stick surfaces. Frequent maintenance guarantees the machine's longevity, giving you dependable service for many years to come. The machine may usually be kept in good operating order with a simple wipe-down after usage.

Roti is a staple in many households, and with the advent of the roti-making machine, preparing this delicious flatbread has become easier and more convenient. Whether you are looking to make traditional plain rotis or want to get creative with different flavors, a roti-making machine can help you achieve perfect results every time. Here are some delicious roti recipes you can make using a roti-making machine.

Classic Whole Wheat Roti:

Ingredients:

2 cups whole wheat flour

1 cup water (adjust as needed)

A pinch of salt

Instructions:

In a mixing bowl, combine the whole wheat flour and salt.

Gradually add water and knead the dough until it is smooth and pliable.

Divide the dough into small balls.

Preheat the roti-making machine and place one dough ball on the machine.

Close the lid and let the roti cook until it is golden brown.

Serve warm with your favorite curry or chutney.

Using a roti-making machine ensures even cooking and a perfect round shape every time.

A roti-making machine can greatly simplify the process of making delicious and diverse roti recipes. From classic whole wheat rotis to creative stuffed variations, these machines ensure consistent results with minimal effort. By incorporating a roti-making machine into your kitchen, you can enjoy the convenience of freshly made rotis without the hassle of traditional preparation methods. Experiment with these recipes and discover the ease and versatility that a roti-making machine brings to your culinary adventures.

0 notes

Text

0 notes

Text

Your Trusted Choice for Commercial Chapati Making Machines in Delhi

Explore Cutting-Edge Chapati Making Machines for Commercial Use in Delhi

Welcome to Mohanlal Kitchen, your trusted destination for top-tier Commercial Chapati Making Machines in Delhi. As a leading manufacturer in the heart of the city, we take immense pride in revolutionizing the culinary landscape with our innovative and efficient chapati-making solutions.

Our Commercial Chapati Making Machines are crafted with precision and state-of-the-art technology, catering to the diverse needs of the bustling food industry in Delhi. We understand the critical role chapatis play in Indian cuisine, and our machines are designed to streamline the production process, ensuring consistent quality and taste.

At Mohanlal Kitchen, we prioritize excellence in both design and functionality. Our Commercial Chapati Making Machines are built to meet the high demands of commercial kitchens, hotels, restaurants, and catering services in Delhi. With user-friendly controls and robust construction, our machines guarantee durability and ease of operation.

What sets our Commercial Chapati Making Machines apart is their ability to produce large quantities of perfectly round and uniformly cooked chapatis in a short span. This not only enhances efficiency in your kitchen but also ensures that your customers enjoy the authentic taste of freshly made chapatis every time.

As a manufacturer deeply rooted in Delhi, we understand the unique challenges and demands of the local culinary scene. Our machines are not only designed for performance but are also tailored to meet the specific requirements of commercial kitchens in the city. From compact models for space optimization to high-capacity machines for large-scale production, Mohanlal Kitchen has the perfect solution for every need.

We take pride in our commitment to customer satisfaction. Our team of experts is dedicated to providing comprehensive support, from the selection of the right Commercial Chapati Making Machine for your business to after-sales service and maintenance. With Mohanlal Kitchen, you’re not just purchasing a machine; you’re investing in a reliable partner for the success of your culinary venture.

If you are in the market for a Commercial Chapati Making Machine in Delhi that combines efficiency, reliability, and innovation, look no further than Mohanlal Kitchen. Our machines are a testament to our passion for culinary excellence, and we invite you to experience the difference they can make in your kitchen. Contact us today to explore our range of Commercial Chapati Making Machines and take a step towards elevating the efficiency and quality of your chapati production.

Unleashing the Power of Innovation with Mohanlal Kitchen

Innovative Technology for Superior Performance

At Mohanlal Kitchen, we pride ourselves on being at the forefront of innovation in the culinary equipment industry. Our Commercial Chapati Making Machines showcase cutting-edge technology, setting new standards for performance and reliability. Explore the fusion of tradition and modernity as our machines revolutionize chapati production, ensuring not only efficiency but also unmatched quality.

Customized Solutions for Varied Needs

Innovation goes beyond just technology; it’s about meeting the unique needs of our diverse clientele. Mohanlal Kitchen offers a range of customizable options, allowing you to tailor our Commercial Chapati Making Machines to your specific requirements. Whether you run a bustling restaurant, a catering service, or a compact kitchen, our innovative solutions can be adapted to elevate your operations.

Smart Automation for Seamless Workflow

Discover the convenience of smart automation integrated into our machines. The intelligent design ensures a seamless workflow, optimizing the production process and reducing manual effort. With Mohanlal Kitchen’s innovative technology, you not only save time but also enhance the overall efficiency of your kitchen, empowering your team to focus on what they do best – creating culinary masterpieces.

Energy-Efficient Solutions for a Sustainable Future

Innovation aligns with sustainability at Mohanlal Kitchen. Our Commercial Chapati Making Machines are not only high-performing but also energy-efficient. We believe in responsible manufacturing, and our innovative solutions contribute to reducing energy consumption, making them environmentally friendly choices for conscious businesses in Delhi.

Constant Evolution for Future-Ready Solutions

The culinary landscape is ever-evolving, and so are we. Mohanlal Kitchen is committed to continuous innovation, ensuring that our Commercial Chapati Making Machines stay ahead of the curve. Our research and development team consistently explores new technologies and advancements to provide you with future-ready solutions that keep your kitchen at the pinnacle of efficiency.

Experience the Future of Chapati Making

In conclusion, Mohanlal Kitchen invites you to embrace the future of chapati production with our innovative solutions. Unleash the power of innovation in your kitchen and witness how our Commercial Chapati Making Machines redefine the standards of performance, customization, and sustainability. Elevate your culinary experience and stay ahead in the dynamic food industry with Mohanlal Kitchen’s commitment to innovation. Contact us today to explore the possibilities that await your kitchen.

Why Choose Our Commercial Chapati Making Machines?

1. Cutting-Edge Technology

Our machines boast cutting-edge technology that sets them apart in the market. Equipped with advanced features, they offer precision and consistency in chapati production. From dough preparation to the final product, our machines guarantee excellence at every stage.

2. Customized Solutions for Every Business

We understand that every commercial kitchen is unique. That’s why our Commercial Chapati Making Machines are available in a range of capacities and configurations to suit the specific requirements of your business. Whether you run a small restaurant or a large-scale catering service, we have the perfect solution for you.

3. Hygiene and Efficiency

Maintaining hygiene in a commercial kitchen is non-negotiable. Our machines are designed with easy-to-clean surfaces and materials, ensuring a hygienic chapati-making process. Additionally, the efficiency of our machines helps save time and resources, contributing to the overall productivity of your kitchen.

4. User-Friendly Operation

Ease of use is a key feature of our Commercial Chapati Making Machines. Designed with the end-user in mind, our machines come with user-friendly interfaces, making them accessible to kitchen staff with varying levels of expertise. This ensures a seamless integration into your kitchen operations.

5. Durability and Reliability

Investing in a Commercial Chapati Making Machine from Mohanlal Kitchen means investing in durability and reliability. Our machines are built to withstand the demands of continuous commercial use, providing you with a long-lasting solution that delivers consistent results.

Elevate Your Kitchen Efficiency with Mohanlal Kitchen

Innovate Your Culinary Workflow

Discover a seamless culinary experience with Mohanlal Kitchen’s cutting-edge kitchen solutions. Our commitment to excellence extends beyond our Commercial Chapati Making Machines. Explore a range of innovative kitchen equipment designed to elevate your kitchen efficiency and redefine the way you cook.

Precision in Every Process

1. Automated Cooking Solutions

Mohanlal Kitchen introduces state-of-the-art automated cooking solutions, reducing manual effort and enhancing precision in every culinary process. From cooking to frying, our machines ensure consistency, allowing you to maintain high-quality standards in your kitchen.

2. Customizable Kitchen Layouts

Efficiency begins with smart kitchen design. Our experts at Mohanlal Kitchen offer personalized consultations to optimize your kitchen layout. Maximize space, workflow, and productivity with custom designs that cater to the specific needs of your culinary establishment.

Unleash the Power of Technology

1. Smart Kitchen Appliances

Embrace the future of cooking with our smart kitchen appliances. From intelligent ovens to advanced grilling systems, Mohanlal Kitchen brings you a range of tech-driven solutions that not only save time but also enhance the overall cooking experience.

2. Energy-Efficient Equipment

Contribute to a sustainable kitchen environment with our energy-efficient equipment. Mohanlal Kitchen prioritizes eco-friendly solutions without compromising on performance, ensuring that your kitchen operations are both cost-effective and environmentally responsible.

Comprehensive Kitchen Support

1. Expert Consultation and Training

Mohanlal Kitchen doesn’t just provide equipment; we offer comprehensive support. Benefit from expert consultations to choose the right kitchen solutions for your needs. Our training programs ensure that your kitchen staff is well-acquainted with the latest technologies, maximizing the potential of our equipment.

2. Responsive Customer Service

Experience peace of mind with our responsive customer service. Anytime you encounter an issue or have a query, our dedicated support team is just a call away. Mohanlal Kitchen is committed to ensuring that your kitchen operations run smoothly without interruptions.

Elevate Your Culinary Experience Today

In conclusion, Mohanlal Kitchen is your partner in transforming a conventional kitchen into an efficient, tech-savvy culinary hub. Elevate your kitchen efficiency with our innovative solutions and experience the perfect blend of tradition and technology. Contact us to explore the full range of kitchen equipment and consultancy services tailored to meet the unique needs of your establishment. Let Mohanlal Kitchen be the catalyst for a new era in your culinary journey.

Why Choose Mohanlal Kitchen?

Industry Expertise: With years of experience in the food industry, Mohanlal Kitchen understands the unique challenges businesses face. Our Commercial Chapati Making Machines are a testament to our commitment to providing practical and effective solutions.

Innovation Driven: Keeping pace with technological advancements, our machines incorporate the latest innovations in chapati making. Stay ahead of the competition by integrating cutting-edge technology into your kitchen.

Customer Support: Beyond delivering top-notch machines, Mohanlal Kitchen is dedicated to providing exceptional customer support. Our team is ready to assist you with any queries, ensuring a smooth and efficient experience with our products.

Elevate your kitchen operations, enhance efficiency, and deliver consistent quality with Mohanlal Kitchen’s Commercial Chapati Making Machines. Contact us today to explore how our innovative solutions can transform your culinary business in Delhi.

#commercial kitchen equipment suppliers#kitchen equipment manufacturers#industrial kitchen equipment manufacturers#supplier kitchen equipment#kitchen equipment supply

1 note

·

View note

Text

Stainless steel plays a crucial role in the manufacturing of commercial chapati machines, due to its durability, versatility, and resistance to corrosion. Stainless steel suppliers provide essential materials like sheets, pipes, and components for building machine frames, cooking plates, and other parts, directly impacting the machine's performance and longevity. Stainless steel welding ensures strong, secure connections between components, making the machines durable even under heavy use and in high-moisture environments. Additionally, stainless steel pipes are vital for functions such as dough transportation, heat regulation, and mechanical movement, ensuring efficient machine operation. MSMEs in India are at the forefront of producing high-quality chapati machines, contributing to the country's economic growth by fostering innovation, creating jobs, and supporting both domestic and export markets. The collaboration between stainless steel suppliers, welding specialists, and MSMEs is integral to the continued success and expansion of the chapati machine industry.

0 notes

Text

Chapati Ball Cutting Machine Manufacturer - S.S Industries

At SS Industries, we understand the significance of perfectly shaped chapati balls in Indian cuisine. To make the process of making chapati balls easier and more efficient, we bring you our top-of-the-line Chapati Ball Cutting Machine. Built with precision and designed to deliver exceptional performance, this machine is a must-have for any commercial kitchen that serves chapati or flatbread on their menu.

Our Chapati Ball Cutting Machine is designed to cut perfectly shaped chapati balls with precision every time. Its advanced technology guarantees uniform size and weight for each ball, ensuring perfectly cooked chapatis every time. Our Chapati Ball Cutting Machine is designed to be easy to clean and maintain. It is constructed with high-quality materials that are durable and long-lasting, ensuring continuous usage in a commercial kitchen. Click here to know more about Chapati Ball Cutting Machine.

S.S Industries

Contact: 95666 81466

Address: 1/2, Sivalpuri Amman Nagar, Nallampalayam, Sanganoor Rd, near Gas Bunk, Sanganoor, Coimbatore, Tamil Nadu 641006

Website: https://murukkumachine.in/

#murukkumachine#thattavadaimachine#machine#foodprocessingmachine#machine manufacturer#machinery#murukku machine

0 notes